Mounted Bearing & Housing manufacturers

Mounted Bearing & Housed Bearing manufacturer

Popular products of steel bearing housing

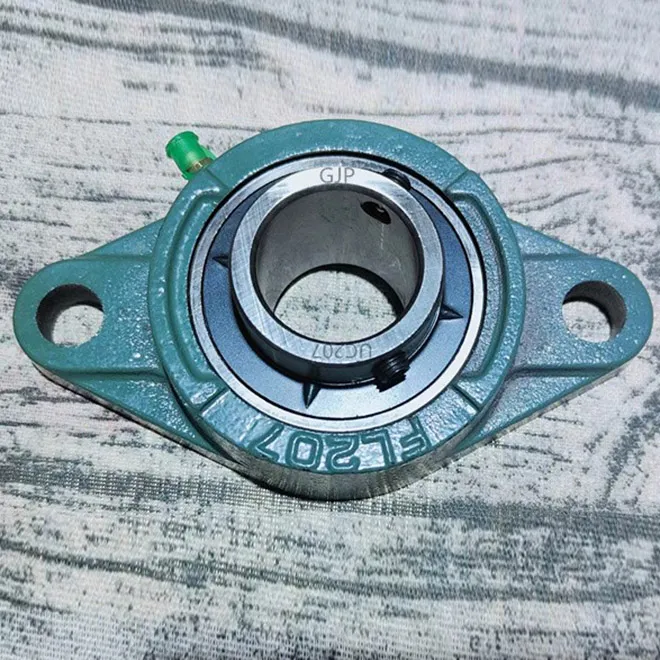

solid base bottom and relubricate grease zerk, This is our hottest product, we produce gray, green, blue, and black shell colors.

GJP 2 bolt flanged mounted bearings UCFLseries, set screw type, J7 tolerance, solid base

3-bolt flange bearings are typically used to support rotating shafts to reduce friction and support the motion of the shaft.

GJP 4-Bolt Flanged Mounted Bearings are produced with top-quality ductile iron QT450 material housing F214.

A take-up bearing unit consists of a housing, which houses the bearing, a take-up frame, and an adjustable steel tube that allows for easy adjustment of the position of the bearing.

ABOUT COMPANY

GJP BEARING company since year 2002

GJP produces different types of top-quality flange bearing units, which include both standard types & custom bearing units. We have been producing full series of top-quality pillow block bearing units, 2 bolts flange holding units, 3 bolts flange bearing units, 4 bolts flange bearing units, take-up bearing units, hanger type bearing units, wide slot take-up bearings, metric tapered roller bearings, triangle flange bearing, pressed steel bearing housing, stainless steel flange bearings, split spherical roller bearing, and other casting parts items, from standard type to hard-to-find sizes.

- GJP bearing brand already has market popularity

- competitive market price

- Wide range of bearing products

- One-stop customized solution

- High-quality bearing housing, outstanding bearing quality

“Some of the History of Our Company is that we are Catching up through Video”

Appointment Video

PROVIDE SERVICE

Advantages

In-stock

In order to meet the urgent needs of dealers, we stock a full range of high-quality UCPX and UCFX and other series of housed bearing units, I believe we are the largest supplier of such bearing units, and our full range of stocks can meet your needs need

Bearing quality

we upgrade our mounted bearing unit quality level, upgrade sealing quality for bearing, and after painting, our pillow block bearings with L3 sealing, turn again the housing base, then put anti-rusty oil on the turning base

Professionalism

We continue to develop new bearing housing products and continuously upgrade our bearing products. We want to be one of the largest suppliers of pedestal housing units in our region

Frequency Ask Question ?

Do you have stock?

For mounted bearing units, GJP is one of your best supplier choice and we have stocks for full series of different type of HCP, UCP, UCF, UCPX, UCFX series to satisfied your urgent demands, and we have some stocks for UCFL,UCPA, UCT series

Is GJP a bearing brand?

Yes, GJP is specialized in producing housed bearings and other types of housed bearing units for 15 years, we specialize in the high quality level of flanged bearing units with reasonable price, if you are interested in becoming our distributor, please give us a call or email me

Does your company produce mounted bearings?

GJP produces UCP series and other series of mounted bearings. We provide cast iron and ductile iron housing materials for customers to choose. Our bearing triple seal design fully protects the product from harmful pollutants and pollution lubrication. We produce gray, green, blue Black, black housing colors, our premium quality bearing units are widely used in agricultural machinery, construction equipment, pumps, manufacturing equipment, sporting and consumer goods, conveying systems, fan assemblies, HAVC systems, feed mills and other industrial applications etc.

The development concept of GJP bearing brand

GJP now focus more on brand promotion and quality level establishing for our pillow block bearings, we are not competing in low grade quality market, and meanwhile we are not greedy to take high profits from our top quality market customers, always think and take good care of our customers and markets, and have mutual benefits are important

how often to grease pillow block bearings?

The lubrication frequency of pillow block bearings depends on various factors, such as application, operating conditions, and bearing type. GJP bearings are lubricated about every three to six months under normal operating conditions. In severe operating conditions, shortened lubrication intervals may be required to ensure optimum lubrication and prevent premature bearing failure.

Applications

Application Field

Conveyor

Our bearings are widely used in conveying equipment, and the flexibility of bearings can better assist the work of conveying equipment.

Construction Machinery

The operating environment of Construction Machinery is relatively harsh. Ordinary bearings may fail after a period of use. It is difficult to repair, replace or even just lubricate the joints. Machine downtime is notoriously expensive and time-consuming. Thanks to seals and robust housings, our bearings have long life and uptime.

Pulp and Paper Mills

The working environment in pulp and paper mills is harsh and dusty. At this time, the use of pulp and paper machines requires good protection in this environment. Bearing units with housings have various structures, good versatility and interchangeability, and very good sealing performance. They can be used in pulp and paper factories. Equipment environment

textile

Bearings with units are high-precision, lubricated parts products suitable for textile and printing and dyeing industries.

Chemical Equipment

Our encapsulated units are well-sealed for simple support. It solves the impregnation problem in the chemical industry very well.

40K

Exporting countries

1000+

number of products

5K +

Customer Satisfaction Number

TESTIMONIAL

What does a client say?

Purchase the stainless steel bearing type you want, or become a GJP distributor

FROM OUR BLOG

Stainless Steel Bearing Knowledeg

UCF215-48 4-Bolt Flange Bearing: Unleashing Precision with a 3” Bore

In the motion control world, the UCF215-48 4-bolt flange bearing is unique for its superior

Unlocked Precision: UCF218 Bearings for Robust Motion Control

Strive for excellence with UCF218 bearings In the world

Understanding Flange Bearings: Benefits and Usage

Flange bearings are cylindrical components with an outer shape much like a washer or a

Understanding the Mechanics of a Flange Bearing

Flange bearings are a type of mechanical bearing that is used to support rotating shafts

The Benefits of Installing Flange Bearings in Your Machinery

Flange bearings are used in many machines, from cars to heavy duty industrial machines. They

A Comprehensive Guide to Understanding Flange Bearings

Flange bearings are used in many industries for a variety of purposes. While understanding the