Many different kinds of machinery and equipment require three bolt flange bearings as a crucial component. They serve as a means of reducing friction between moving elements and supporting spinning shafts. These bearings are made up of a locking collar, a bearing insert, and a flange with three bolt holes. We shall examine the definition, characteristics, benefits, uses, and range of three bolt flange bearings in this post.

What is the definition of a three bolt flange bearing?

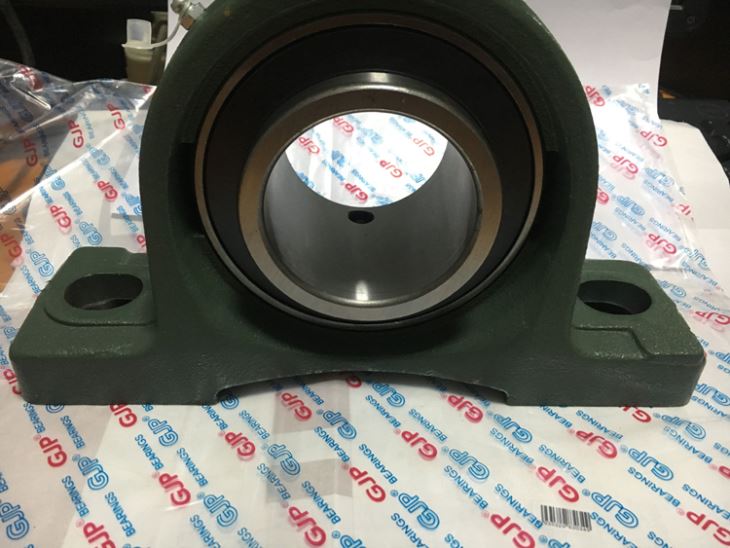

A form of bearing made to support rotating shafts in many sorts of machinery is called a three bolt flange bearing. It comprises of a bearing insert that fits within the flange and a flange with three bolt holes that is attached to a shaft. Balls or rollers in the bearing insert enable it to spin freely and lessen friction between moving elements. The locking collar holds the bearing insert firmly in place and guards against it sliding or shifting.

What Characterizes Three Bolt Flange Bearings as Special?

The longevity, substantial load capacity, and adaptability of three bolt flange bearings are well recognized. They are resistant to corrosion and wear because they are composed of high-quality materials like stainless steel, cast iron, or thermoplastic. Heavy weights and a variety of speeds and applications are both suited for three bolt flange bearings. They are additionally simple to install, maintain, and replace.

Advantages: Why Choose Three Bolt Flange Bearings?

In comparison to other types of bearings, three bolt flange bearings are favored due to their numerous benefits. First off, they eliminate downtime and require little maintenance, which lowers costs and lengthens the lifespan of equipment. Second, they are adaptable and may be utilized in a variety of pieces of machinery, including pumps, machines, and conveyors. Thirdly, they are a great source of support and contribute to noise and vibration reduction.

Applications: What Are the Uses of Three Bolt Flange Bearings?

Construction, automotive, aerospace, and the manufacturing sectors all often employ three bolt flange bearings. They support spinning shafts in conveyor systems, printing presses, packing equipment, and textile machinery. They also serve to lessen friction and sustain large loads in pumps, fans, and motors. They support big loads and lessen wear and tear in lift trucks, cranes, and forklifts used in the construction sector.

What should procurement managers take into account when purchasing three-bolt flange bearings?

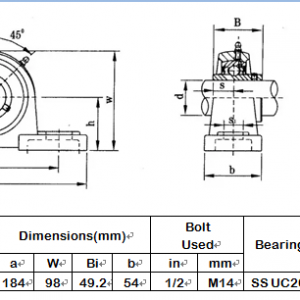

When purchasing three bolt flange bearings, procurement managers should take a number of considerations into account. They should first check to see if the bearing is constructed of high-quality components and is appropriate for the application. Second, they should think about the bearing’s temperature range, speed, and load capability. The bearing’s compatibility with the shaft, seal, and lubrication system should be checked out third. The supplier’s pricing, delivery schedule, and warranty should also be taken into account.

When purchasing three bolt flange bearings, procurement managers should take a number of considerations into account. They should first check to see if the bearing is constructed of high-quality components and is appropriate for the application. Second, they should think about the bearing’s temperature range, speed, and load capability. The bearing’s compatibility with the shaft, seal, and lubrication system should be checked out third. The supplier’s pricing, delivery schedule, and warranty should also be taken into account.

Related Products