Square flange bearings in standard are essential in many industrial applications, ranging from heavy machinery to food processing equipment. They are designed to provide support and alignment for rotating shafts, ensuring smooth and efficient operation. However, with so many options available, selecting the right square flange bearing for your application can take time. In this article, we will discuss the factors affecting precision and reliability and guide you in choosing the best square flange bearing for your needs.

Understanding Square Flange Bearings

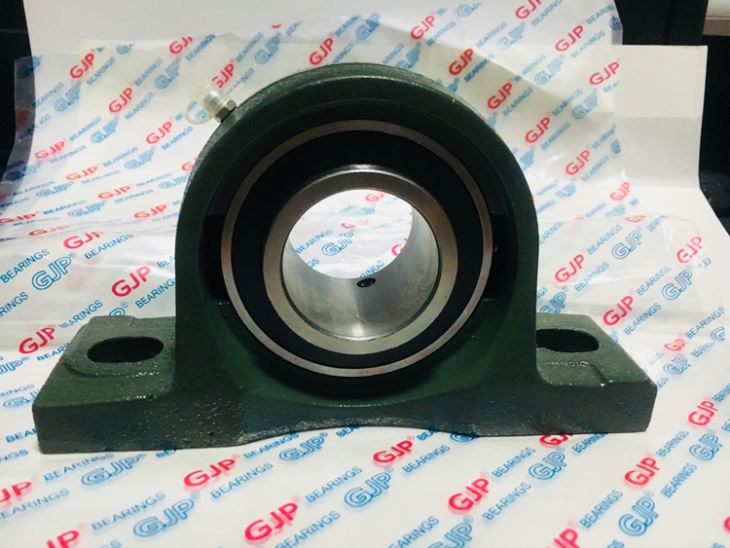

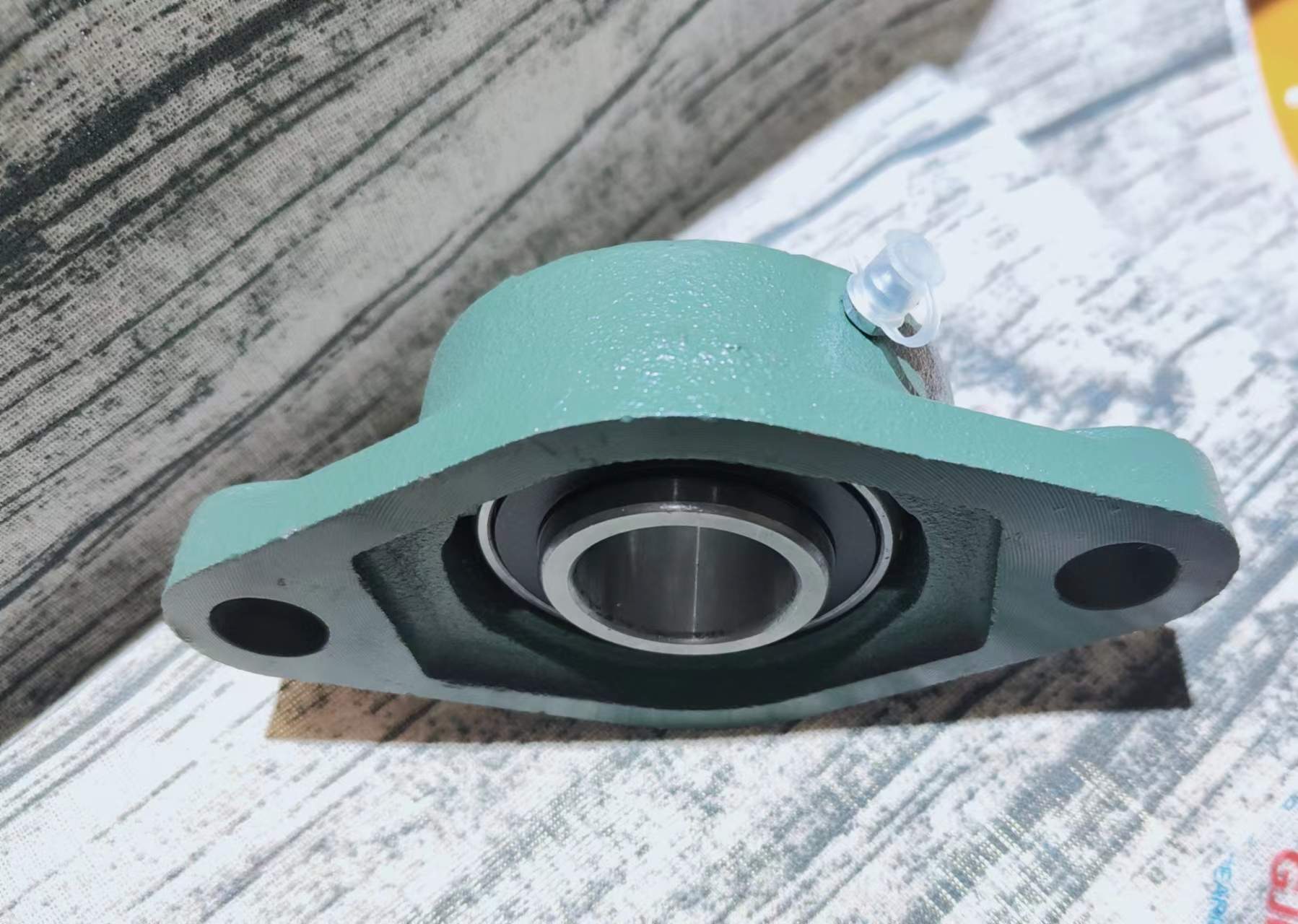

Before diving into the details, let’s define what square flange bearings from china are. A square flange bearing from China is a type of mounted bearing that consists of a housing and an insert bearing. The housing has a flat surface with four mounting holes, which allows it to be bolted to a support structure. The insert bearing fits inside the housing and rotates around a shaft.

Square flange bearings are available in various sizes and materials, including stainless steel, cast iron, and thermoplastic. They also come with different seals and locking mechanisms, such as set screws or eccentric collars. Your bearing will depend on your specific application and the environmental conditions it will be exposed.

Factors Affecting Precision

Precision is critical in many applications, especially those that require high speeds, high loads, or precise alignment. A poorly selected bearing can result in vibration, noise, or premature failure, leading to costly downtime and repairs. Here are some factors that affect precision:

1. Shaft and Housing Tolerances

The shaft and housing tolerances are the maximum allowable deviations from the specified dimensions. The closer the tolerances, the more precise the bearing will be. Therefore, ensuring that the shaft and housing are manufactured to the correct tolerances is crucial to avoid any misalignment.

2. Bearing Clearances

The bearing clearance is the gap between the bearing’s inner and outer rings. It affects the bearing’s stiffness and ability to handle radial and axial loads. Too much clearance can lead to vibration and noise, while too little clearance can cause excessive friction and heat buildup. Therefore, choosing a bearing with the appropriate clearance for your application is essential.

3. Lubrication

Lubrication reduces friction and wears between the bearing and the shaft. Insufficient or improper lubrication can cause premature failure, while over-lubrication can lead to overheating and damage to the seals. Therefore, selecting the proper lubricant and applying it correctly is essential.

Factors Affecting Reliability

Reliability is essential in any application, ensuring the equipment operates consistently and without interruption. Here are some factors that affect reliability:

1. Load Capacity

The load capacity is the maximum force the bearing can withstand without failing. It depends on the bearing’s size, material, and design. Therefore, choosing a bearing with a load capacity that meets or exceeds your application’s requirements is crucial.

2. Environmental Conditions

Environmental conditions, such as temperature, humidity, and contaminants, can affect the bearing’s performance and lifespan. Therefore, choosing a bearing that can withstand the environmental conditions it will be exposed to is crucial.

3. Installation and Maintenance

Proper installation and maintenance are crucial in ensuring the bearing’s reliability. Improper installation can cause misalignment or damage to the bearing, while inadequate maintenance can lead to premature failure. Therefore, following the manufacturer’s instructions for installation and maintenance is essential.

Choosing the Right Square Flange Bearing

Now that we have discussed the factors affecting precision and reliability, let’s look at how to choose the correct square flange bearing for your application. Here are some steps to follow:

1. Determine the Load and Speed Requirements

The first step in selecting a square flange bearing is to determine your application’s load and speed requirements. The load capacity of the bearing should be equal to or greater than the maximum load expected in your application. The speed rating of the bearing should also be sufficient for the rotational speed of your application.

2. Consider Environmental Conditions

The environmental conditions in which the bearing will operate are critical in selecting the right square flange bearing. For example, if your application is exposed to high temperatures, you should choose a bearing with a high-temperature rating. If your application is exposed to corrosive materials, you should choose a bearing made of corrosion-resistant material.

3. Select the Right Type of Bearing

There are several types of square flange bearings, including ball bearings, roller bearings, and plain bearings. Each type has its advantages and disadvantages, so it’s essential to choose the right type for your application. For example, ball bearings are suitable for high-speed applications with low to moderate loads, while roller bearings are better for heavier loads.

4. Choose the Right Material

The material of the bearing will affect its durability, corrosion resistance, and temperature tolerance. Stainless steel is an excellent choice for applications that require corrosion resistance, while cast iron is a good choice for heavy-duty applications. Thermoplastic bearings are suitable for applications where weight and noise reduction are essential.

5. Determine the Lubrication Requirements

Lubrication is essential in ensuring the bearing’s reliability and longevity. Determine the lubrication requirements of your application and choose a bearing that can handle the lubrication method you plan to use.

Conclusion

Choosing the right square flange bearing for your application requires careful consideration of several factors, including precision, reliability, load capacity, environmental conditions, and lubrication requirements. By following the steps outlined in this article, you can select the best square flange bearing for your needs, ensuring the smooth and efficient operation of your equipment. Remember to follow the manufacturer’s instructions for installation and maintenance to maximize the bearing’s reliability and longevity.

Related Products