1.1 What is a pillow block bearing and what is it used for?

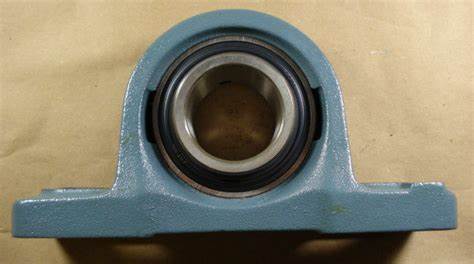

Pillow bearings are a type of housed bearing, a type of bearing used to support a rotating shaft. Pillow bearings are typically used in applications where the shaft is subject to a lot of wear or there is a lot of vibration. Pillow bearings consist of two main parts: the housing and the bearing. The housing is the part that attaches to the shaft, and the bearing is the part that supports the shaft. Mounted bearings come in a variety of sizes and configurations, so you can find the one that is right for your application.

1.2 What are the benefits of using pillow block bearings?

There are many benefits to using pillow block bearings. Some benefits include: increased accuracy, increased speed, increased reliability, and increased durability. These bearings help improve the efficiency and performance of machines.

1.3 How do pillow block bearing units work?

Bearing housings are structures that support the rotating shaft with a bearing. The housing contains a number of ball bearings that support the shaft and allow it to rotate freely. Block housings are often used in applications where the bearings are heavily loaded or where high speeds are required.

1.4 What are the common applications of pillow block bearings?

Pillow bearings are used in a wide variety of applications, some of the most common applications include conveyor systems, packaging equipment and material handling systems. Pillowcase bearings are also used in a variety of industrial and commercial applications.

2. What types of pillow block bearings are there?

2.1 What is a pillow block bearing?

A mounted bearing, also known as a plummer bearing, is a type of bearing that supports a rotating shaft. It consists of a housing and a bearing assembly mounted on the housing. Bearing assemblies include bearings and housings. Shaft bearings are mounted in the housing and allow the shaft to rotate. Housing bearings are installed in the housing and support the weight of the bearing assembly.

2.2 Types of spherical bearings with pillows

There are several different types of pillow block bearings. The most common type is the standard pillow bearing, which is a simple bearing held in place with two or more bolts. There are also flanged pillow block bearings, which have a flange on one side to help hold them in place. Finally there is the bearing adapter, which is a type of bearing used to fit different types of bearings into specific applications.

2.3 How to use pillow block bearings

There are several different types of pillow inserts. The most common type is the U-shape, which has two flanges on either side of the bearing. The flange helps to hold the bearing in place. Another type of pillow bearing is the H type, which has a flange on one side of the bearing. This type is less common than the U-type.

To use a pillow insert bearing, you need to first determine what type of bearing you have. After determining the bearing type, it is necessary to determine the installation hole position. The mounting hole is the hole in the bearing used to mount the bearing on the shaft. Once the mounting holes are identified, the bearing can be mounted to the shaft using a mounting kit.

3. How to install the pillow block bearing seat?

3.1 How to install the pillow block bearing unit on the shaft.

There are four steps in mounting a bearing unit on a shaft. The first step is to measure the diameter of the shaft. You need to make sure the shaft is the right size for the bearing. The next step is to apply a light coat of grease to the shaft. This will help the bearings slide easily. The third step is to insert the bearings onto the shaft. You may need to use a hammer to tap the bearings into place. The fourth and final step is to tighten the set screws on the bearings. This will hold the bearing in place.

3.2 How to install pillow block bearings using holes.

Installing pillow block bearings can be a daunting task, but using holes can make the process much easier. First, remove the old bearings and clean the shaft with solvent. Next, apply a light coat of lubricant to the shaft and insert the new bearings. Finally, turn the hole clockwise to install the bearing.

3.3 How to install bearing units with clips.

Mounted bearing blocks can be installed in a few simple steps. First, remove the clips from the bearings. Then, install the bearing into the housing. Finally, install the clips onto the bearings.

3.4 How to install the pillow block bearing housing with set screws.

The first step is to identify the mounting holes on the block. There are two mounting holes on each side of the block. These holes are used to mount the block to a surface or to mount an axle through the block.

Next, insert the set screw into the mounting hole closest to the shaft. Set screws should be inserted until the screws are flush with the surface of the block.

Finally, use the hex wrench to tighten the set screw. Be sure to tighten the screw until it is snug against the shaft.

4. How to maintain the pillow block bearing?

4.1 How to clean pillow block bearings

Pillow bearings can be lubricated manually or automatically and must be kept clean to operate effectively. To clean pillow mount bearings, you will need to remove the end caps and clean the bearings with solvent. Then you can replace the end caps and lubricate the bearings.

4.2 How to Lubricate Bearing Units

To lubricate a housed bearing, you will need to apply a light coat of lubricant to the shaft and bearing races. You can use a variety of lubricants, such as grease, oil, or dry film lubricant. Make sure to apply a light coat of lubricant, taking care not to get on the seals or bearing housing.

4.3 How to adjust the pillow block bearing

To adjust the pillow block bearing, loosen the bolts that hold the bearing in place. Then, use a wrench to turn the adjusting screw on the bearing. Turn the screw until the bearing is in the desired position. Finally, tighten the bolts to secure the bearings in place.

5. What are the potential problems of pillow block bearings?

5.1 What are the potential problems with pillow block bearings?

Potential problems with pillow block bearings are loud noise, oil leakage and rapid wear.

5.2 What are the potential problems with using pillow block bearings?

The main potential problem with using pillow block bearings is that they are prone to wear and are also prone to leaks. If any of these problems occur, it can cause serious problems for the machinery supported by the bearings.

5.3 What are the potential problems with table bearings in the system?

A mounted bearing is a type of bearing that is often used in systems with a large amount of movement. However, there are some potential problems that can arise when using these bearings. One problem is that they can loosen over time, causing the system to malfunction. Also, if the bearings are not lubricated properly, they can overheat and damage the system.

5.4 What are the potential problems with housed bearings in the factory?

In the factory, housings can experience problems such as overheating, vibration and friction. If these problems occur, the bearings may need to be replaced, which can be expensive. To avoid these problems, it is important to ensure that the bearings are properly lubricated and the plant is properly cooled.

5.5 What are the potential problems with factory pillow block bearings?

Factory workers often use mounted bearings in machines to help them move and connect parts. However, there are some potential problems with their use. One is that they create a lot of friction, which heats up the parts they work on and causes them to wear out faster. Another is that they can be noisy and generate a lot of vibrations that can be disturbing or even harmful to workers.

A pillow block bearing is a type of bearing used to support a rotating shaft. This type of bearing is typically used in applications where there is a lot of vibration or where space is limited. Pillow block bearings come in a variety of different sizes and styles, so it’s important to know what type of bearing you need before purchasing one.

Related Products