I believe that many people mention stainless steel flange bearings, only know that this is a material that is not easy to rust, but this does not mean that it will not rust, and stainless steel will also corrode and rust under certain conditions. Therefore, bearings made of stainless steel also need to be rust-proof and maintained.

The main reasons for the chemical corrosion of stainless steel flange bearings are as follows:

- Surface scratches: All kinds of scratches will lead to the destruction of the passivation film on the surface of the bearing, which will reduce the protective performance of stainless steel, and cause the scratched parts to easily react with chemical media, resulting in chemical corrosion and rust.

- Improper cleaning: When pickling and passivating, because the degree of cleaning is not clean enough, there will be residual liquid on the surface, which will cause the bearing to corrode.

- Surface pollution: Dust, oil, and various acids, alkalis, salts and other chemical components attached to the bearing surface will corrode the bearing and cause it to rust. Because certain ingredients in stainless steel will react chemically with some elements, causing it to rust.

- Defects in raw materials: There are chemical defects in raw materials for making stainless steel flange bearings, such as uneven composition, doping with impurities, etc., and there are physical defects in their appearance, such as cracks, looseness, etc. The corrosive medium constitutes chemical corrosion.

It can be said that stainless steel flange bearings are subject to rust, and rust will greatly affect the stability of their operation. Therefore, it is necessary to do a good job of anti-rust work. Anti-rust work mainly starts from avoiding the occurrence of corrosive conditions. For example, try to avoid scratches on the surface of the bearing, and wear gloves when installing and dismounting, so as to avoid stains from injuries and sweat stains from corroding the bearing.

Factors affecting the service life of stainless steel flange bearings

Stainless steel flange bearings are relatively durable and have a long service life. However, during use, the bearings will be affected by factors such as temperature, load, vibration, lubrication, and the environment, resulting in shortened service life. Let’s analyze them one by one below. .

1. Lubricate.

Good lubrication keeps the bearings running smoothly.

2. Temperature.

Stainless steel flange bearings are under high temperature, which can easily lead to oil film damage, and the bearing itself will generate heat during continuous operation. In addition to using high-temperature grease, it is also necessary to pay attention to heat dissipation.

3. Seal.

Under certain working conditions, the bearing needs to be directly exposed to the external environment, which will also shorten the service life of the bearing. For bearings with special installation positions, it is necessary to pay attention to the sealing of the bearings.

4. Load.

Bearings with different specifications and types can bear different radial and axial loads. If the bearing is overloaded for a long time, it will inevitably lead to shortened service life.

5. Vibration and shock.

In the case of proper lubrication, the work of vibration reduction, anti-vibration and impact resistance should be done well to avoid damage to the bearing caused by vibration and impact.

6. Environment.

For example, humidity, sea water or other environmental factors will also have some impact on the bearing.

For example, if the water content in the bearing is relatively large, it will accelerate the rust and oxidation of the bearing, which will reduce the life of the bearing sharply. In addition, the accuracy of installation will also affect the service life of stainless steel deep groove ball bearings, especially improper preload, when the coaxiality is too large, it not only affects the service life of the bearing, but also affects the stability of operation.

Nowadays, there are many mechanical equipment and instruments that need to use stainless steel flange bearings. Generally, bearings can be used stably only after correct assembly and use, reasonable lubrication conditions and a good operating environment, but failures during use are inevitable. The following will list its common failures, causes and solutions.

Fault 1: Abnormal temperature rise Reason: Inappropriate lubricant addition. For example, the amount of lubricant added is not enough, or too much will cause the temperature of the stainless steel bearing to rise abnormally during operation. In addition, the creep of the mating surface and the poor sealing performance of the sealing device will also increase the temperature together.

Solution: ①Add suitable lubricant; ②Adjust the inner and outer diameter of the bearing; ③Replace the sealing device.

Fault 2: Large rotational vibration of the shaft Cause: The main shaft of stainless steel flange bearings is fatigued and peeled off during long-term operation, or there are foreign objects in the bearing that cause the bearing to vibrate, and there are installation errors during installation.

Solution: ① replace the new bearing; ② clean the bearing and add suitable lubricant; ③ improve the installation method.

Fault 3: Strong metal sound Reason: Abnormal load, poor assembly, insufficient lubricant will cause such faults.

Solutions: ① Choose a matching clearance and a suitable preload; ② Correct assembly to improve the accuracy of the shaft; ③ Use suitable lubricants.

Fault 4: Lubricant leakage Cause: Excessive lubricant added or foreign matter invaded.

Solution: Reduce lubricant and thoroughly clean the parts inside the stainless steel bearing.

The above are the common faults, causes and solutions during the use of stainless steel flange bearings. After reading it, have you mastered the causes and solutions of its faults?

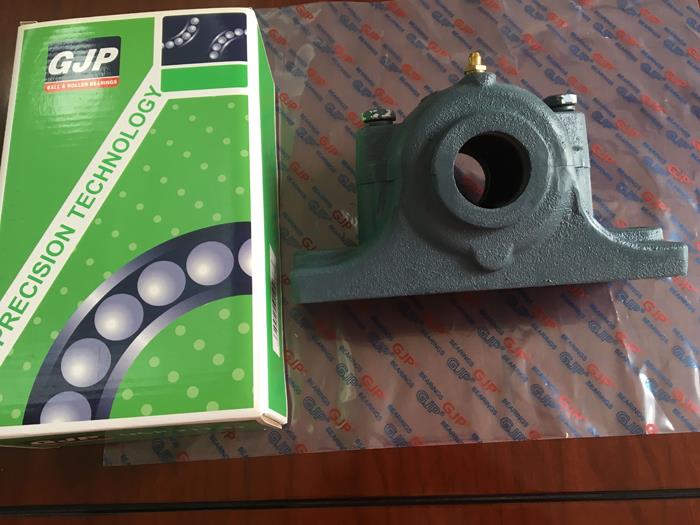

Xiamen Smark Bearing is one of the biggest exporter for pillow block bearing. As a China ucp bearing exporter, we have two factories, which has totally 120 staffs. Smark, as an exporter of bearing housing flange bearings, helps customers install and debug bearings, make bearings run more standardizedly, prolong bearing service life, and provide customers with training services to allow customers to use bearings more reasonably.