Compared with ordinary bearings, stainless steel bearings not only have obvious material advantages, but also in terms of technology and precision control, they are much stricter than ordinary bearings. During the working process, the stainless steel bearing has stable operation, low noise, corrosion resistance and wide application.

Advantages of stainless steel bearings

- Excellent corrosion resistance: stainless steel bearings are not easy to rust and have strong corrosion resistance.

- Washable: We all know that many iron and steel things will rust after washing, but stainless steel bearings can be washed with water and do not need to be lubricated again after washing.

- General materials should not be used in liquids because general corrosion and rust will occur after prolonged exposure.But stainless steel bearings can be used in liquids because the raw materials used in stainless steel can run in liquids.

- Slower depletion: AISI 316 stainless steel does not require oil or grease for corrosion protection. Therefore, if the speed and load are low, no lubrication is required.

- Hygiene: Due to its good corrosion resistance, stainless steel bearings can always be kept in a very clean state.

- High heat resistance: it can operate normally in a relatively high temperature range.

The distinction between 304 and 440 stainless steel bearing materials

- Stainless steel bearings are now divided into three materials: 440, 304, and 316. The first two belong to the more common stainless steel bearings.

- 440 material is definitely magnetic, that is, magnets can be attracted. 304 and 316 are micro-magnetic (many people say that it is not magnetic), that is, the magnet can’t attract, but you can feel a little suction. Generally, stainless steel bearing seats are made of 304 material.

So what is the material of the stainless steel bearing seat is 304 or 440?

304 is the most used stainless steel, and the price is lower than 440. Considering the anti-corrosion ability and mechanical properties, the comprehensive performance is more comprehensive, so it is widely used.

But the disadvantage is that further heat treatment cannot be carried out to change its properties.

440 is a high-strength cutting tool steel. After proper heat treatment, a higher yield strength can be obtained, and it is among the hardest stainless steel. The most common application example is “razor blades”.

Countermeasures for Problems in Stainless Steel Bearings

1. Bearing heat

If the bearing lubricating oil is insufficient, add oil and check whether the oil circuit is unobstructed; if the lubricating oil has impurities, clean the bearing, replace the new oil, and clean the filter; Add a gasket at the bottom of the bearing seat; if the bearing clearance is too small, the clearance should be readjusted.

2. Shaft heating

If the oil block or rubber sealing ring on the shaft is too tight, the position of the back cover of the packing should be adjusted; if there is radial friction between the shaft and the stainless steel bearing cover, the radial clearance between the shaft and the bearing cover should be checked and adjusted, generally 0.25~0.3mm.

3. Less oil on the main friction surface

If the oil pipe is blocked and the oil groove is shallow, the pipe should be cleaned and the oil groove should be deepened; If the oil temperature is low and the fluidity is poor, the lubricating oil should be replaced according to the ambient temperature; If the oil level is too high, the oil can be drained to the standard height; if the adjusting gasket blocks the lubricating oil, the position of the adjusting gasket should be checked.

4. Oil spill

If there is too much oil, the oil supply should be adjusted to maintain the standard height of the oil level; if the sealing device fails, the gland should be pressed, the felt ring should be thickened or the sealing material should be replaced; if the bearing seat has holes and oil seeps, the bearing seat should be replaced or plug the pores with lead filling.

5. Axial runout

If the bearing clearance is too large, the gasket should be removed and adjusted; if the dynamic balance of the rotating body (gear, belt wheel, etc.) is not good, the dynamic balance should be checked and adjusted; if the bearing is unstable, the bearing seat bolts should be tightened; If the installation offset of the shaft coupling is large, shims should be added to the ground of the bearing seat to adjust the installation accuracy of the coupling.

6. Fracture failure of stainless steel bearings

The main reasons for the failure of stainless steel bearings are defects and overload. When the applied load exceeds the material strength limit and the part breaks, it is called overload fracture. The main reason for overload is the sudden failure of the host or improper installation. Defects such as micro-cracks, shrinkage holes, air bubbles, large foreign debris, overheated tissue and local burns in bearing parts will also cause fractures at the defects during shock overload or severe vibration, which is called defect fracture.

It should be pointed out that during the manufacturing process of the bearing, the re-inspection of the raw materials, the quality control of forging and heat treatment, and the control of the processing process can be accurately analyzed by instruments to determine whether the above defects exist, and the control must be strengthened in the future. But in general, most of the common stainless steel bearing fracture failures are overload failures.

7. Response plan for deformation and maintenance of stainless steel bearings

A. Use reasonable cooling methods:

The influence of the cooling process on the deformation after metal quenching is also an important cause of deformation. Hot oil quenching has smaller deformation than cold oil quenching, and is generally controlled at 100±20℃. The cooling capacity of the oil is also critical to deformation. Both the stirring method and speed of quenching affect the deformation. The faster the cooling rate of the metal heat treatment, the more uneven the cooling, the greater the stress, and the greater the change of the mold.

B. Use a suitable medium:

Under the premise of ensuring the same hardness requirements, try to use oily medium. Experiments and practice have proved that under the premise of no difference in other conditions, the cooling rate of oily medium is slower, while the cooling rate of water-based medium is relatively faster.

C. The structure of the parts should be reasonable:

During the cooling process of metal after heat treatment, the thin part always cools quickly and the thick part cools slowly.

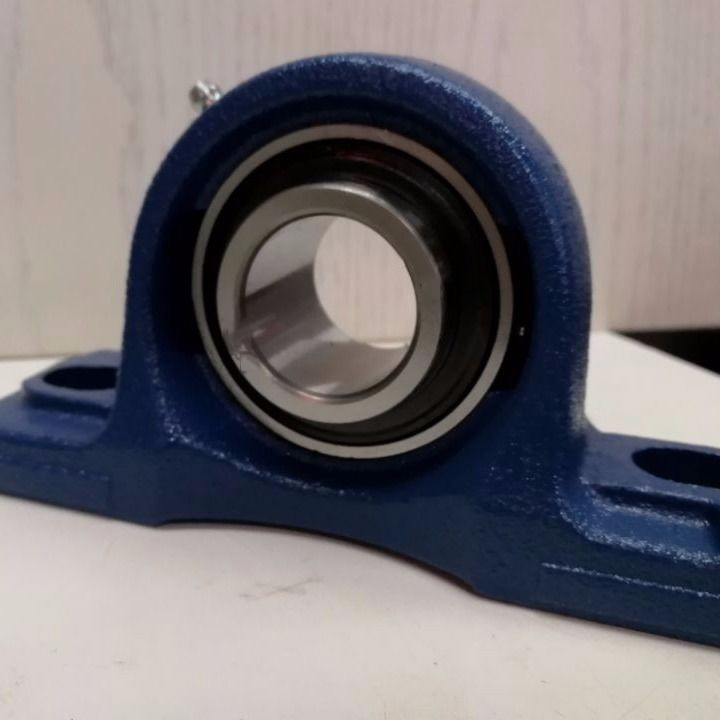

Xiamen Smark Bearing is a professional pillow block flange bearing exporter, and now we are one of the biggest exporters for pillow block bearing. We have advanced technology and excellent product quality, if you are interested in our products, welcome to come to consult.